PROCESSING INSTRUCTIONS

THERMAX® Fire protection boards

With fire protection constructions made of THERMAX® fire protection boards safety standards are met at the highest level. In order to ensure the quality standard also at installing THERMAX® fire protection constructions, consider the following recommendations and instructions for handling and processing:

General Information

- Linings with fire protection boards should not be put up in buildings with prolonged relative humidity of more than 80%, in accordance with DIN 18181.

- Avoid fast, shock-like heating of the rooms as this can cause cracks in the boards.

- Avoid direct exposure of the board surface to hot or warm airflow.

- Screed or wet plaster should be left to dry up after applying and if hot asphalt is used, it should be left to cool down and dry up before leveling/ spackling is carried out.

- Leveling/ spackling works may only be performed after no major changes due to temperature changes etc. are to be expected in the length of the fire protection boards.

- Leveling/ spackling shall not be carried out if room temperature is lower than +10°C.

Storage / Internal transport

General information about storage conditions

The moisture content of fire protection boards coming from the factory is between 2 to 6 %, but this initial moisture content can change during transport and temporary storage. Boards have to be protected from wet conditions, and should be stored in closed and dry areas, where air humidity should not exceed 80% and the temperature should not be lower than 0 °C.

Storage / Internal transport

To avoid deformation and breaking of boards, THERMAX® must be transported and stored on original pallets supplied by the manufacturer. If boards are restacked, strong enough pallets with chipboard base shall be used.

Improper storage of boards, e.g. vertical or without a full-surface support, will lead to deformations that may affect further processing and later on the assembly.

No more than 2 original THERMAX® pallets shall be stacked. If opened or used pallets are stacked, their height must not exceed the maximum height of 2 original pallets. To secure loads vertically, it must always be ensured that pallet feet are always in a vertical line above each other. The boards on pallets in use shall be protected with a cover layer (e.g. chipboard, etc.) and wrapped in a loose foil.

For transport with forklift, a fork distance of more than > 90 cm is recommended.

Single boards have to be carried vertically, meaning upright, by two people.

Tools / Equipment

THERMAX® fire protection boards can be safely processed with conventional woodworking tools and machines (drilling, milling, sawing, sanding, etc.) and without any issues regarding work hygiene or environmental impact.

Standard woodworking tools and machines are suitable for blanks, whose blades have the usual carbide tipped tooth shapes.

Recommended cutting tools:

- Blades for board thicknesses up to 20 mm

- Hand or tenon saw

- Circular hand saw with guide rails

- Jigsaw for cutouts and adjustment works

- Portable circular saw for construction site

- Fully automatic cutting machine, stationary or mobile, for prefabrication in a workshop.

Chamfer the edges of the visible side with a knife or edge planning tool.

Exhaustion

Dust produced during processing should be sucked off in principle. The dust is noncombustible – in anyhow, a separate dust extraction is recommended for larger processing amounts, legal regulations must be observed.

Board jointing

Butt jointing

THERMAX® fire protection boards can be butt jointed.

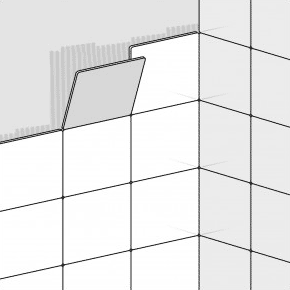

Corner jointing

THERMAX® fire protection boards can be fixed together by means of screws or staples. Depending on construction requirements, additional gluing may be necessary.

Gluing

On one hand, our special THERMAX® fire protection glue is an optimal assembly aid, on the other hand it air-and-smoke-tight-seals installations joints of ventilation and smoke extraction ducts.

THERMAX® fire protection glue shall be applied at temperatures above +5 °C. Higher temperatures accelerate the time of binding process, lower temperatures prolong it.

After economical application of the glue onto the surfaces, the boards can be screwed or stapled together.

The glue is best applied directly from the tube to the surface. Superfluous glue should be removed with a spatula.

THERMAX® fire protetection boards can also be bonded to each other. The glue is applied with a notched trowel and the boards are pressed together.

THERMAX® fire protection glue is supplied in tubes and buckets. The safety instructions printed on the glue packing shall be observed.

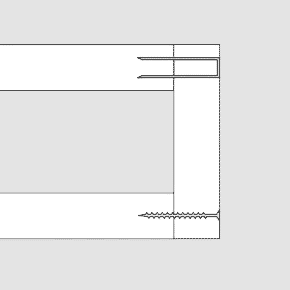

Screws

Coarse thread screws with partial threading, e.g. spax screws, are required. The screw length must be at least twice the board thickness, unless construction datasheet requires otherwise.

Screws must not be over tightened and it shall be ensured that screw heads are leveled with the board surface.

Screwing in sheet profiles is done with drywall screws.

By fixing THERMAX® fire protection boards directly under trapezoidal profile sheets, drywall screws with drill bit are to be used.

Staples

Galvanized steel wire staples, with or without adhesive varnish, can also be used for corner connections of THERMAX® fire protection construction.

Along with connection with THERMAX® fire protection glue, stapling also results in a safe and durable construction connection. Staplers with pressure limiters should be used.

THERMAX® Joint Filler or Surface Coat are used for leveling screw heads and staple points.

Coating / Paints

Before leveling and preparing further coating, pre-treat the entire surface with solvent-free deep primer, which is appropriate for the subsequent coating, such as point, wallpaper, finishing coat or tiles.

Coating and Filling

Only dry boards are to be installed. The internal temperature must not be below +10 °C; the facade must be closed. Screed or we plaster should be left to dry up after applying and if hot asphalt is used, it should be left to cool down and dry before leveling is carried out.

THERMAX® Joint Filler or THERMAX® Surface Coat shall be used in accordance with the instructions on their packing or with the information in the chapter on accessory products.

Board joints have to be leveled on areas where later plaster or paint will be applied. We recommend to use THERMAX® Joint Filler, which is pressed into the joint by reinforced strips (fiberglass mesh). The joint filler swells in the joint and connects to the board edge, rests can be removed after about 20 minutes.

The surface of the THERMAX® fire protection board must be free of dirt, separating substances and dry.

The surface of the THERMAX® fire protection boards is chamfered before leveling. Leveling works may only be performed when no major changes due to temperature changes, etc. in length of the fire protection boards are to be expected. To ensure a crack-free joint formation, the substructure has to be prepared adequately.

Expansion joints are to be installed for large areas.

By applying THERMAX® Surface Coat a smooth transition to the board surface can be achieved.

Paints and Finishes

Practically all common wall paints and finishes can be applied to the THERMAX® fire protection boards. In addition to mineral paints also synthetic resin paints, silicone inks, plastic emulsion paints, varnishes and DD- or PE- coatings can be applied.

Priming on raw boards

By priming the absorbency of the surface is reduced and reaches a secure basis for the subsequent surface design.

Clean light and colorfast surfaces of dispersion, resin or acrylic paint are achieved by applying a spatula coat, a primer and a topcoat.

(see also: THERMAX® Impregnation S)

Priming on paperfaced boards

On paperfaced boards, a smooth surface is already achieved with one or two topcoats. A surface coat is only necessary where the boards have asperities.

(see also: THERMAX® Impregnation M)

Plastering / Wallpapering / Tiling

Plastering

Due to excellent dimensional stability, our THERMAX® fire protection boards are especially suitable for plasterwork. As preparation, a dispersion primer with quartz sand can be applied onto the raw board or decorative plasters by the thin-bed method, e.g. Disbon- or Alseco-plasters.

THERMAX® fire protection boards are also a suitable base for sound insulation plasters.

Wallpapering

Without problems, THERMAX® fire protection boards can be decorated with various wallpapers of different qualities. The use of suitable base coat holing primer is required.

Tiles

THERMAX® fire protection boards can be covered with tile, ceramic, or natural stone surfaces. All board joints, both horizontal and vertical, have to be reinforced with joint reinforcement tapes, and then leveled out as a whole.

Appropriate provisions for tile coverings must be observed.